Evisu is now re-launching its brand with a new collection for men and women (from $150 to $700 a pair). The collection pays homage to the fascinating and forgotten roots of the brand. The re-launch of Evisu will focus on the quality, craftsmanship, and authenticity that made them the IT jeans in late-90s, when there was a long waiting list for the 12 pairs that Barneys received each month. Evisu was also the first denim brand to sell in mass for over $100 a pair.

In 1988, Hidehiko Yamane, an avid denim collector, importer, and tailor by trade, set out to replicate the American classic 1944 Levi’s 501 with an obsessive attention to detail. He founded Evisu in 1991 in Osaka, Japan, naming the company after the Japanese god of prosperity, who is sometimes playfully portrayed on the label. Evisu is one of the five unofficial members of what most people in the denim industry know as ‘the Osaka Five’; the five most influential and respected denim brands in Japanese denim history. For 2010, in preparation for the new decade and the commemoration of Evisu’s 20th anniversary, the design baton for Evisu was passed to American designer Scott Morrison. The overall rebranding and updated style changes of the new 2010 collections reflect Scott Morrison’s signature approach to denim. Morrison is considered by many as a pioneer in the denim world, founding and designing both Paper Denim & Cloth and Earnest Sewn. With his arrival at Evisu, he and his team have brought a renewed focus to denim, fit and wash, as well as an updated approach to Evisu the international brand.

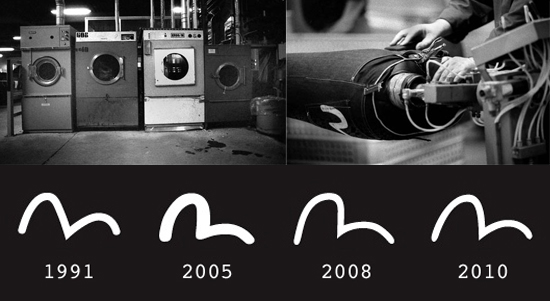

Besides using the best Selvedge denim in the world, Evisu jeans go through a “dry” and “wet” process” that gives each pair its unique look and can take up to one week for a pair to be finally ready. The dry process is completed by hand. The uniqueness of each garment is created during the dry process as a craftsman hand-sands one piece at a time on an apparatus called a “Sanding Tandem” and uses hand applied scrapping tools to create vintage effects, forgoing molds or more conventional methods. Wet process is completed in washing machines. Resin, color treatments and other liquids are applied. The jeans are then put into a bath with an enzyme or stone wash giving each pair its unique look and feel.